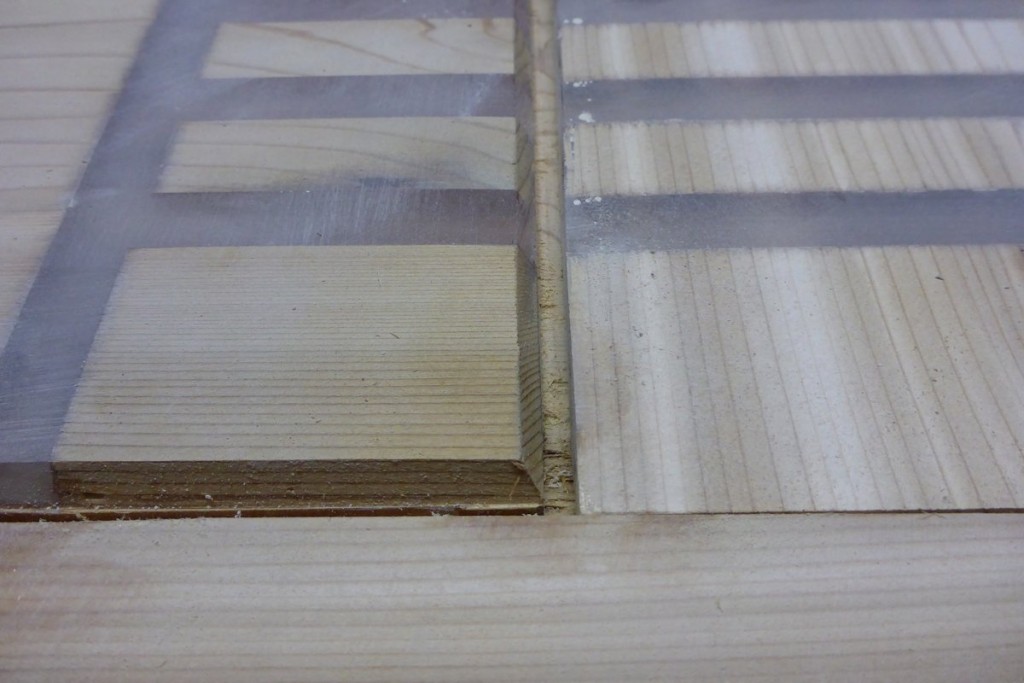

We continue to be impressed with Marc’s attention to detail on our front door. He sent us some photos of the finishing process, which involves sanding the resin, bevelling edges, and touching up some of the gaps. I wrote the captions, apologies to Marc if anything I say is inaccurate.

Because this is a front door, it is subject to extreme temperature and humidity changes. The interior may be hot and m-m-m– humid, and the exterior may be cold and dry. So the panels of the door float freely so they can expand and contract without causing the door to buckle. That’s why the pretty design has narrow gaps where the panels meet the stiles (outer parts of the door). The resin can’t be used in these gaps. When we worked on the design, Marc and I made sure that not too much of the design would be lost in the gaps.

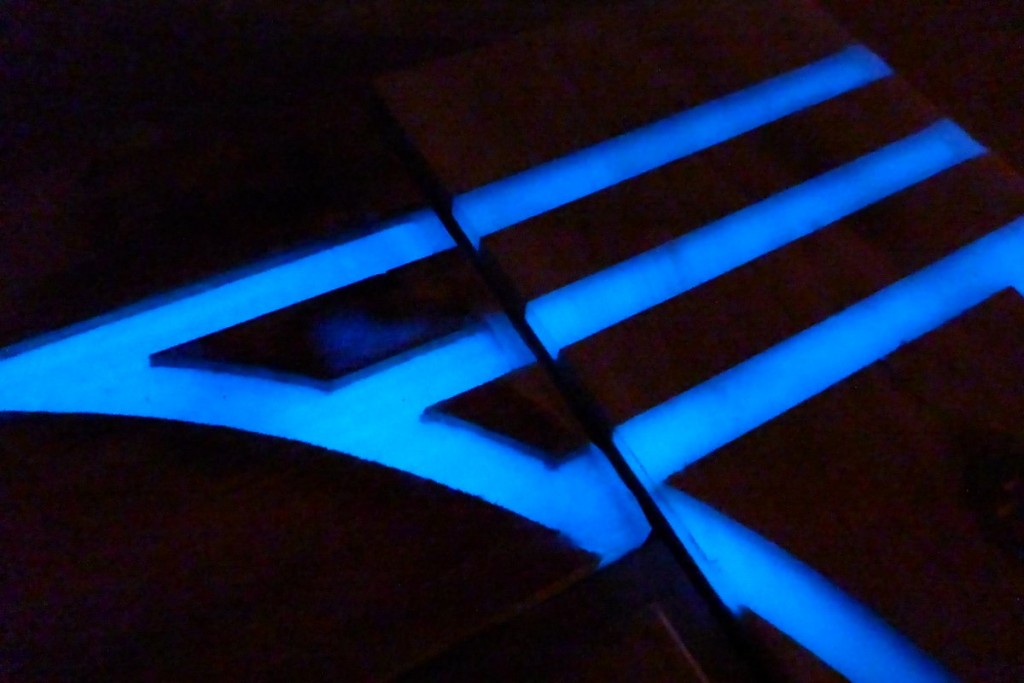

We have already talked with our electrician, Alex, about making sure that the door gets properly illuminated during the day so it glows at night. He seemed to think that ambient light would do the trick, but with such a centerpiece we’ll do whatever it takes to make sure the resin gets properly charged.